December 2009

Well Christmas has come and gone by the time you read this and I hope it was a good one for you all.

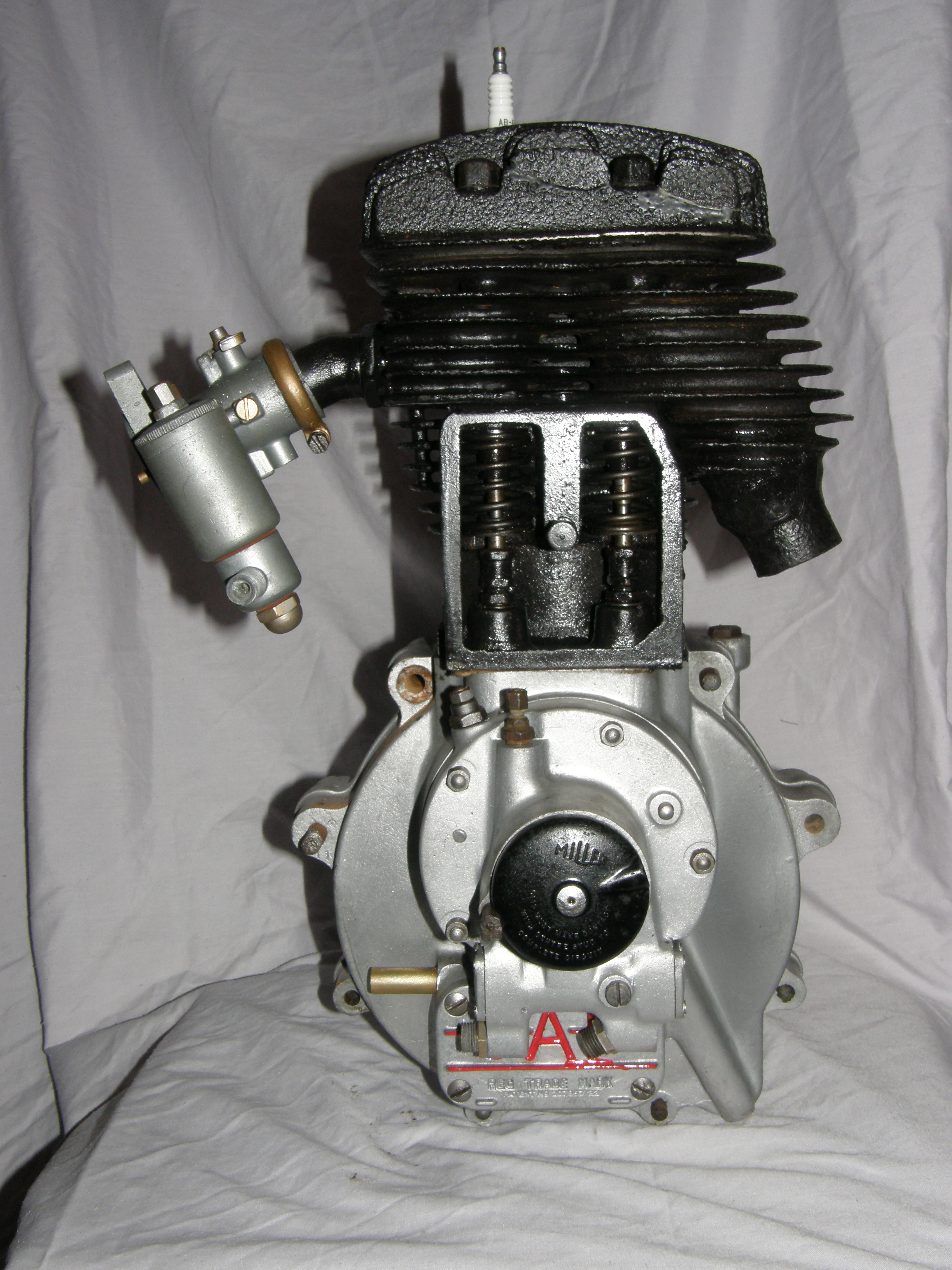

Work has been done on 35 as I had a few days off during the festive week. I have now ground the valves in the inlet one needing less work than the exhaust. The pain came when going to refit the collets. Normally I would use my valve spring compressor that my dad made me but being a side valve meant that there was no room for it to fit in. This meant that I needed an extra pair of hands to do the job as I had to use two screw drivers to compress the spring enough to clear the indent where the collets sit. Once done I then had to place the collets in their location while holding the spring back and doing my best not to fire them across the room in to a deep dark corner never to be seen again. After what seemed an age I got all four in place so then set about adjusting the valve clearance. This seemed odd from the normal way as there are no tappets as such just adjustable caps on top of the push rods. This though was still a pain and also could have done with three hands.

All was soon done and so the head got refitted and bolted down. I have not done it dead tight yet in case I need to remove it to check the timing again once the engine is in the chassis.

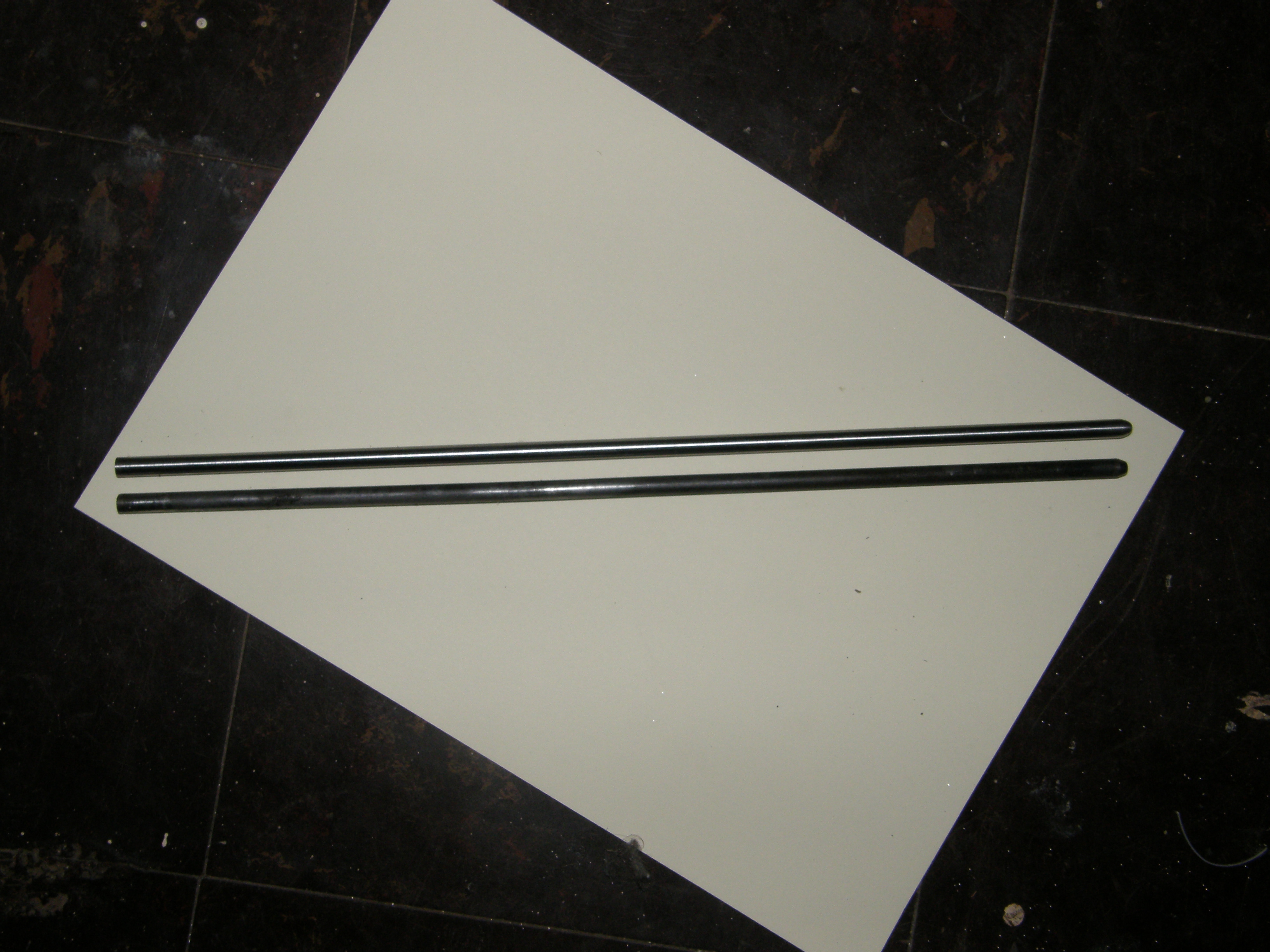

The gear box is now also complete apart from a few new bolts needed and a thread chaser to run down the mount studs to clean them up. The one thing that I notice was that the clutch rod that goes though the centre of the gear box was about 6mm (1/4”) short. All I can think is that it worn away over the years of clutch operation. So it was off to George Engineering who made me a new one out of silver steel and once in placed seemed to work just like it should. I am still having problems at the min in locating what grease goes in the gear box if anyone has a clue please drop me an e-mail.

My shot blaster is now up and working so all the little things now like the engine mounting plates can be shot blasted before being painted and boy it makes the job so easy now, no more wire bush.

I have also sorted out the last two chassis rails that need repairing and cut off the bad sections and will have some plate bent to their profile so that it can be welded back on to the end. I have been toying with the idea once all the chassis bits are done to have them galvo dipped. I met a lady at the museum who is part of a family company that are the last hand dippers and have been going for over 100 years. So I will let you know what I decided next update.

I also need to sort out the box of bolts as I want to renew them all and West Brom Fasteners will match my bolts for me, and even supply stronger ones to hold the axle on.

Only a short update this month and the problem is I know and I am (so I feel) a little behind schedule so I must try and get back on track.

Till next time thanks for reading and have a great New Year

Setting the valve gaps any one got a spare hand

New Clutch rod made of tool steel

Finished engine but need valve cover

Restored Gearbox with Kick start

If you find any missing or broken links please let me know at geoff@35reliant.co.uk. And if you have any information on Reliant pre 1952 please get in touch at the above e-mail address as I would love to hear from you.

1935 Reliant

Jan 2024

Last Update